Dust Collector

The Vibratory dust collector has been designed for installation on top of silos, bins and hoppers.

They come with a cylindrical stainless-steel casing and flanged bottom ring, which contains vertically mounted cartridge filter elements, which are cleaned by an electric motor vibrator.

Normally the dust collector with fan is used in the above of the concrete mixer.

| Model |

Dedusting area(㎡) |

Dedusting volume(m³/h) |

Qty of dustbags(pcs) |

Motor capacity(kw) |

Air storage volume(L) |

Compressed air(Bar) |

| DC20/2 |

20 |

2400 |

16 |

2.2 |

14 |

4~7 |

| DC24/2 |

24 |

2800 |

20 |

2.2 |

14 |

4~7 |

| Filtration area | The maximum air volume | Filtration efficiency | Cleaning system | Connection mode | Weight |

| 24㎡ | 1500m³/h | 99.90% | Vibration type | Flange connection | 100kg |

| Model | Dedusting area(㎡) | Dedusting volume(m³/h) | Qty of dustbags(pcs) | Motor capacity(kw) | Air storage volume(L) | Compressed air(Bar) |

| DC20/0A | 20 | 2400 | 16 | - | 14 | 4~7 |

| DC20/2 | 20 | 2400 | 16 | 2.2 | 14 | 4~7 |

| DC24/0 | 24 | 2800 | 20 | - | 14 | 4~7 |

| DC24/2 | 24 | 2800 | 20 | 2.2 | 14 | 4~7 |

Pressure Relief Valve

On top of silos and bins, hoppers or container to avoid over pressure and negative pressure .

To prevent problems which could severely damage both silo and filter.

The material of the air pressure relief is stainless steel and the main body is made from carbon steel .

Pressure Relief Valve

Level indicators are designed for level monitoring of bins, hoppers or silo by means of the rotating paddle, when the material level reaches the measuring paddle the rotation is blocked .The motor is freely suspended within the casing.

The resulting reaction torque activates a limit switch output signal that stops the motor.

Normally our cement silo is installed 2 level indicator , checking the maximum horizontal level and also minimum installation level, 24V and 22v is both available.

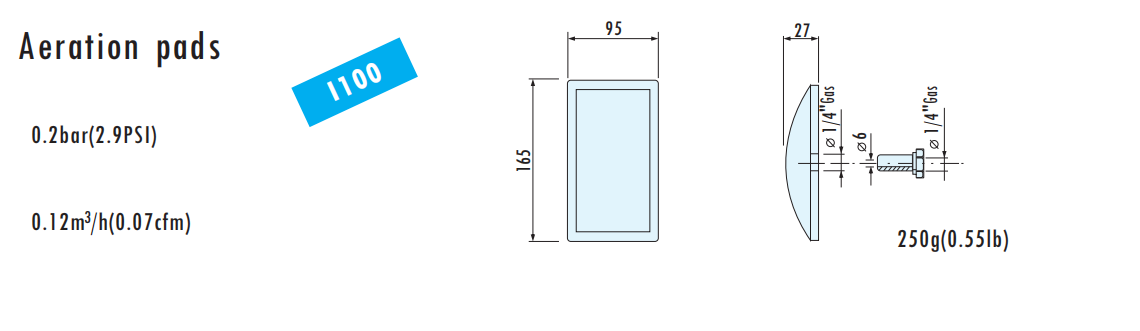

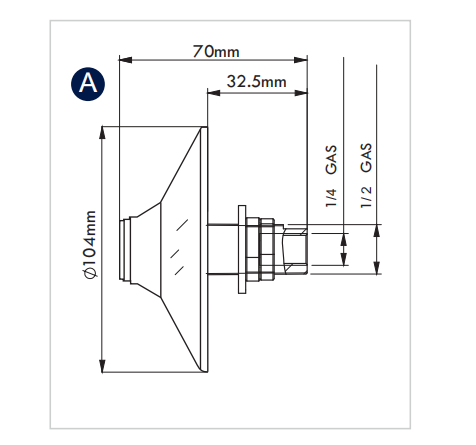

Bin Aerator & Air Pad & Air Nozzle

Due to the characteristic of the cement or fly ash, inside silo , hoppers,chutes, piping or any other containers will tend to stick to the surface . Those flow aids are designed to solve issue caused by design error or by the characteristic of the powder . Moreover, they increase process efficiency and improve plant safety

We choose one type of flow aids for our cement silo .

| VB | I | E | |

| Type | BLANK:Standard aerator | BLANK:AluminiumI:Stainless steel | BLANK:StandardE:External Mounting |

DK25

Performance & Technical Features – Benefits

* Suitable for cement, lime and similar powders

* Working temperature: -20 to 230° C (-4 to 450° F)

* Material: carbon steel

* Suitable for cement, lime and similar powders