Operation and maintenance of concrete mixer,

China Concrete Mixing Plant, Concrete Batching Plant,

The HZS series concrete mixing plant is a is a strong manufacturing and high-efficiency equipment that can produce various kinds of concrete. With high production efficiency, it is widely used in large and medium-sized building construction, road axial engineering and necessary factories for producing concrete products. It is an ideal equipment for producing commercial concrete. Its mixing system adopts a twin shaft compulsory mixer, which has good mixing uniformity, short mixing time, long service life of wearing parts, and convenient operation and maintenance. It adopts the latest control technology such as electronic weighing system, computer control and digital display. Electronic weighing devices are equipped with buffer devices and automatic compensation functions, with high measurement accuracy. The sand and gravel feeding system adopts a large width herringbone belt for feeding and is equipped with sidewalks. It is an ideal choice for a large number of construction units to produce the best concrete.

DKTEC can easily meet customer needs through its fixed concrete mixing plants of different capacities and specifications.

It has a variety of fixed concrete batching equipment, and the production capacity of a mixer ranges from 60m³/h to 180m³/h. We can also customize solutions according to customer needs, our email: sales@dongkunchina.com

In addition, in the same fixed concrete mixing plant with dual mixers, the production capacity can reach 240 cubic meters/hour and 360 cubic meters/hour.

HZS series concrete mixing plant is composed of Mixing system, Material batching system, Weighing system and Electrical control system. It is suitable for large and small construction sites, precast concrete product plants and production plants.

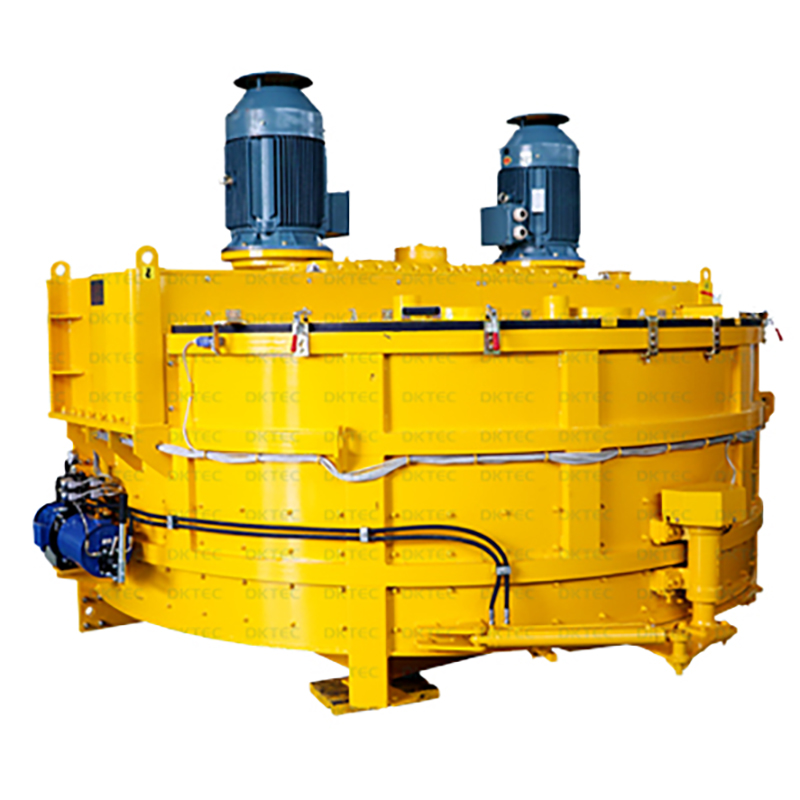

Mixing system

Twin shaft concrete mixer has strong mixing capacity, uniform mixing quality and high productivity. It has good mixing effect for concrete with dry hardness, semi-dry hardness, plasticity and various proportions. The lubrication system and the main shaft drive system are all imported from the original package, and the hydraulic door opening mechanism can adjust the opening of the discharge door as required. The mixing shaft of the main mixing machine adopts anti-adhesion technology to effectively prevent the agglomeration of cement on the shaft. The shaft end seal adopts a unique multiple sealing structure to effectively prevent mortar leakage and ensure the continuous and long-term operation of the entire mixing system. The cleaning system adopts high-pressure water pump automatic control and manual control,The water outlet holes are located directly above the mixing spindle, which improves the mixing efficiency, increases water mist, reduces dust pollution and effectively removes cement agglomeration. It is suitable for large-scale construction, commercial concrete companies, etc.

Twin-shaft concrete mixer

Learn more

Planetary mixer

Learn more

Aggregate Batching System

Choose a batching machine; the feeding mechanism is arranged in a “product” shape and fed by a belt conveyor; it adopts two methods of individual material weighing and cumulative material weighing; electronic weighing, PLC control, digital display; t has accurate weighing, high batching precision, fast speed, strong control function, easy operation, etc.

Control System

Apply imported components, reliable performance; remote management, user rights can be assigned, achieve the basic project management processes; intelligent control, automatic control, manual control in one; with ratio storage, automatic drop compensation, over-scale, under-scale alarm correction; The equipment has functions such as operation monitoring, data cloud storage, printing, etc.

Weighting System

The powder, water, and additives are all measured by electronic scales; the batching accuracy is high and the measurement is accurate; the cement, fly ash, and water measuring hopper is supported on the frame by three sets of sensor, which has a stable structure and high reliability; the additive metering hopper is measured by a single lifting point sensor

Each mixing plant is tailor-made for customers!

The price of each batching plant varies due to different configurations!

If you need to know the detailed price information of the small mixing station, you can directly call our sales hotline: 0086-571-88128581

According to the configuration you need, we will provide accurate quotation and let you get the information you need in a short time!

Maintenance of concrete mixer

1.Ensure that the machine and the surrounding environment are clean.

2.Clear the accumulated material in the hopper in time to make the sensor return to zero normally.

3.Check whether the lubricating oil at each lubrication point is sufficient, and the lubricator in the air system should maintain sufficient oil.

4.Check whether the motors and electrical appliances are overheated or abnormal noise, whether the indicator is normal, and whether the signal system is intact.

5.Check and adjust the cylinder, butterfly valve and solenoid valve frequently to make the opening and closing meet the requirements.

6.Check each system frequently, and deal with it in time if there is dust leakage, gas leakage, oil leakage and electricity leakage.

7.The mixer and discharge hopper should be cleaned every four hours to prevent the residual concrete from consolidating and hindering normal operation.

8.Every shift should release the internal water of the air compressor, air storage tank and filter, and eliminate the malfunctions that occur during operation.

9.The butterfly valve, mixer, solenoid valve, air filter and oil mist device are maintained in accordance with the relevant instructions.

1. Xīn jī shǐyòng qián yīng ànzhào hùnníngtǔ jiǎobànjī shǐyòng shuōmíngshū de yāoqiú, duì gè xìtǒng hé bùjiàn zhú xiàng jìnxíng jiǎnyàn jí bìyào de shì yùnzhuǎn. Kōng chē yùnzhuǎn, jiǎnchá jiǎobàn tǒng huò jiǎobàn yè de zhuǎndòng fāngxiàng, gè gōngzuò zhuāngzhì de cāozuò, zhì dòng, quèrèn zhèngcháng, fāng kě zuòyè. 2, Gùdìng shì hùnníngtǔ jiǎobànjī, yīng ānzhuāng zài láogù de táizuò shàng. Dāng chángqí shǐyòng shí, yīng mái zhìdì jiǎo luóshuān. Rú duǎnqí shǐyòng, kě zài jī zuò xià pūshè zhěnmù bìng zhǎopíng fàng wěn. 3, Duìyú yídòng shì hùnníngtǔ jiǎobànjī, yīng ānzhuāng zài píngtǎn jiānyìng dì dì píng shàng yòng fāng mù huò chēng jià jià láo, bìng bǎochí shuǐpíngmiàn lúntāi bù shòu lì. Rúguǒ shǐyòng shíjiān chāoguò sān gè yuè yǐshàng shí, yīng jiāng lúntāi xiè xià tuǒshàn bǎoguǎn lúnzhóu duān bù yīng zuò hǎo qīngjié fáng xiù gōngzuò. 4, Duì mǒu xiē xūyào wā shè shàng liàodòu dì kēng de jiǎobànjī, qí kēngkǒu zhōuwéi yīng diàn gāo hāngshí, yǐ fáng dìmiàn shuǐ liúrù kēngnèi. Shàng liào guǐdào jià de dǐ duān zhīchéng miàn yīng hāngshí huò pù zhuān, jià de hòumiàn yì xū yòng mùliào jiāyǐ zhīchéng, fángzhǐ gōngzuò shí guǐdào biànxíng. 5, Hùnníngtǔ jiǎobànjī qǐdòng hòu, yīng shǐ jiǎobàn tǒng dádào zhèngcháng zhuǎnsù hòu jìnxíng shàng liào, shàng liào hòu yào jíshí jiāshuǐ. Tiānjiā xīn liào bìxū xiān jiāng jiǎobànjī nèiyuán yǒu de hùnníngtǔ quánbù xiè chū hòu cáinéng jìnxíng. Bùdé zhōngtú tíngjī huò mǎn zǎihé shí qǐdòng jiǎobànjī, fǎn zhuǎn chū liào zhě chúwài. 6, Zài hùnníngtǔ jiǎobànjī shǐyòng zhōng, qiè wù shǐ shā shí luò rù jīqì yùnzhuǎn bùfèn zhōng qù, yǐmiǎn shǐ yùnzhuǎn bùjiàn kǎ zhù sǔnhuài. Shàng liàodòu tíshēng hòu, dòu xià bùnéng yǒurén tōngguò huò tíngliú, yǐmiǎn zhìdòngqì shīlíng fāshēng yìwài shìgù. Rú bì zài dòu xià jiǎnxiū huò jìnxíng qīnglǐ gōngzuò shí, qiángxíng tíngjī bìng jiāng shàng liàodòu yòng bǎoxiǎn liàntiáo lā láo. 7, Jiǎobànjī zuòyè zhōng, rú fà xiàn gùzhàng bùnéng jìxù yùnzhuǎn shí, yīng lìjí qiēduàn diànyuán, jiāng jiǎobàn tǒng nèi de hùnníngtǔ qīngchú gānjìng, ránhòu jìnxíng jiǎnxiū. 8, Zuòyè hòu, yìngduì jiǎobànjī jìnxíng quánmiàn qīngxǐ, cāozuò rényuán rú xūyào jìnrù tǒng nèi qīngxǐ shí, bìxū qiēduàn diànyuán, shè zhuānrén zàiwài jiānhù, huò xiè qù róngduàn qì bìng suǒ hǎo diànzhá xiāng, ránhòu fāng kě jìnrù. 9, Jiǎobànjī shàng liàodòu de yáo bǎ, yìngyòng xiāo zǐ gùdìng, yǐmiǎn rén jìnrù jiǎn nèi qīnglǐ shí, shēntǐ pèng chù yáo bǎ shǐ liàodòu tíshēng, fāshēng jǐ yā shìgù. 10, Zuòyè hòu, yīng jiāng jiǎobànjī liàodòu jiàngluò dào liàodòu kēng, rú xū shēng qǐ zé yìngyòng liàntiáo kòu láo.

展开

723 / 5000

翻译结果

1. Before the new machine is used, each system and components should be inspected and necessary trial run in accordance with the requirements of the concrete mixer manual. Run empty, check the rotation direction of the mixing drum or mixing blade, the operation and braking of each working device, and confirm that it is normal before operation.

2. The fixed concrete mixer should be installed on a firm stand. When used for a long time, anchor bolts should be embedded. For short-term use, you can lay sleepers under the machine base and level it.

3. For the mobile concrete mixer, it should be installed on a flat and hard floor with square timbers or support frames, and the horizontal tires should not be stressed. If it is used for more than three months, the tire should be removed and the end of the axle should be cleaned and rust-proof.

4. For some mixers that need to dig the pit of the upper hopper, the surrounding of the pit should be padded and compacted to prevent ground water from flowing into the pit. The supporting surface of the bottom end of the loading track frame should be compacted or laid bricks, and the back of the frame should also be supported with wood to prevent the track from being deformed during work.

5. After the concrete mixer is started, the mixing drum should reach the normal speed before loading, and water should be added in time after loading. Adding new materials must first unload all the original concrete in the mixer before proceeding. Do not stop the mixer halfway or start the mixer at full load, except for the reverse discharge.

6. During the use of the concrete mixer, do not let sand and gravel fall into the running part of the machine, so as to avoid jamming and damage to the running parts. After the upper hopper is lifted, no one can pass or stay under the hopper to avoid accidents caused by brake failure. If it is necessary to perform maintenance or cleaning under the hopper, shut down forcibly and fasten the upper hopper with a safety chain.

7. During the operation of the mixer, if it is found that there is a failure and cannot continue to operate, the power supply should be cut off immediately, the concrete in the mixing drum should be cleaned, and then the maintenance should be carried out.

8. After the operation, the mixer should be thoroughly cleaned. If the operator needs to enter the barrel for cleaning, he must cut off the power supply and set up a special person to monitor it, or remove the fuse and lock the switch box before entering.

9. The handle of the hopper on the mixer should be fixed with a pin to prevent people from touching the handle to lift the hopper and causing a squeezing accident.

10. After the operation, the mixer hopper should be lowered to the hopper pit, and the chain should be used to fasten it if it needs to be raised.

![LH~{3}TCP(C]$4PYZ70WR$5](https://www.batchingplantchina.com/uploads/LH3TCPC4PYZ70WR5.jpg)